The

powder coat curing oven serves as a pivotal component within the powder coating process. Principally, there are two primary types. The benchtop

powder coat curing oven, with a starting price of approximately $800, is highly suitable for small - scale operations such as hobbyist workshops or small - scale DIY projects. Characterized by its compact design, user - friendly control mechanisms, and a relatively small heating chamber, it caters to the needs of low - volume production. In contrast, the industrial - grade

powder coat curing oven, commencing at $10,000, is engineered for large - scale manufacturing. It is equipped with a large - capacity chamber, precise temperature - control systems, and high - power heating elements, which facilitate efficient curing processes.

These ovens function by elevating the temperature of powder - coated workpieces to a specific threshold. This thermal treatment fuses the powder particles, resulting in a smooth and durable finish. Constructed with high - quality insulation materials, these ovens are designed to ensure energy - efficiency. Suppliers typically provide installation guidance, training in operation and maintenance procedures, and post - sales support services.

In the jewelry - making industry, benchtop ovens find application in curing powder - coated jewelry components. Within the automotive parts manufacturing sector, industrial - grade ovens are employed to cure the powder coatings on engine components and body parts. In metal furniture production, the choice between the two types of ovens is contingent upon the production scale.

Question: How does one determine the appropriate temperature setting for a powder coat curing oven?

Answer: One should consult the powder manufacturer's guidelines for the recommended curing temperature. Subsequently, utilize the oven's temperature - control panel to set the desired value.

Question: What measures can be taken if bubbles appear in the powder coating after curing?

Answer: This phenomenon may be attributed to over - heating or entrapped air. It is advisable to slightly reduce the curing temperature or pre - heat the workpiece to eliminate moisture.

Question: Is it possible to use the oven for different types of powder?

Answer: Yes, it is feasible. However, it is essential to thoroughly clean the oven between different powder types to prevent cross - contamination.

Question: How frequently should a powder coat curing oven be cleaned?

Answer: Cleaning is recommended after every 5 - 10 uses. Remove any powder residue and conduct a visual inspection for signs of wear and tear.

Question: How does one select the most suitable powder coat curing oven?

Answer: The selection should be based on considerations such as production volume, budget constraints, and the required level of precision. For small - scale projects, a benchtop oven is often adequate. For large - scale production, an industrial - grade oven is more appropriate.

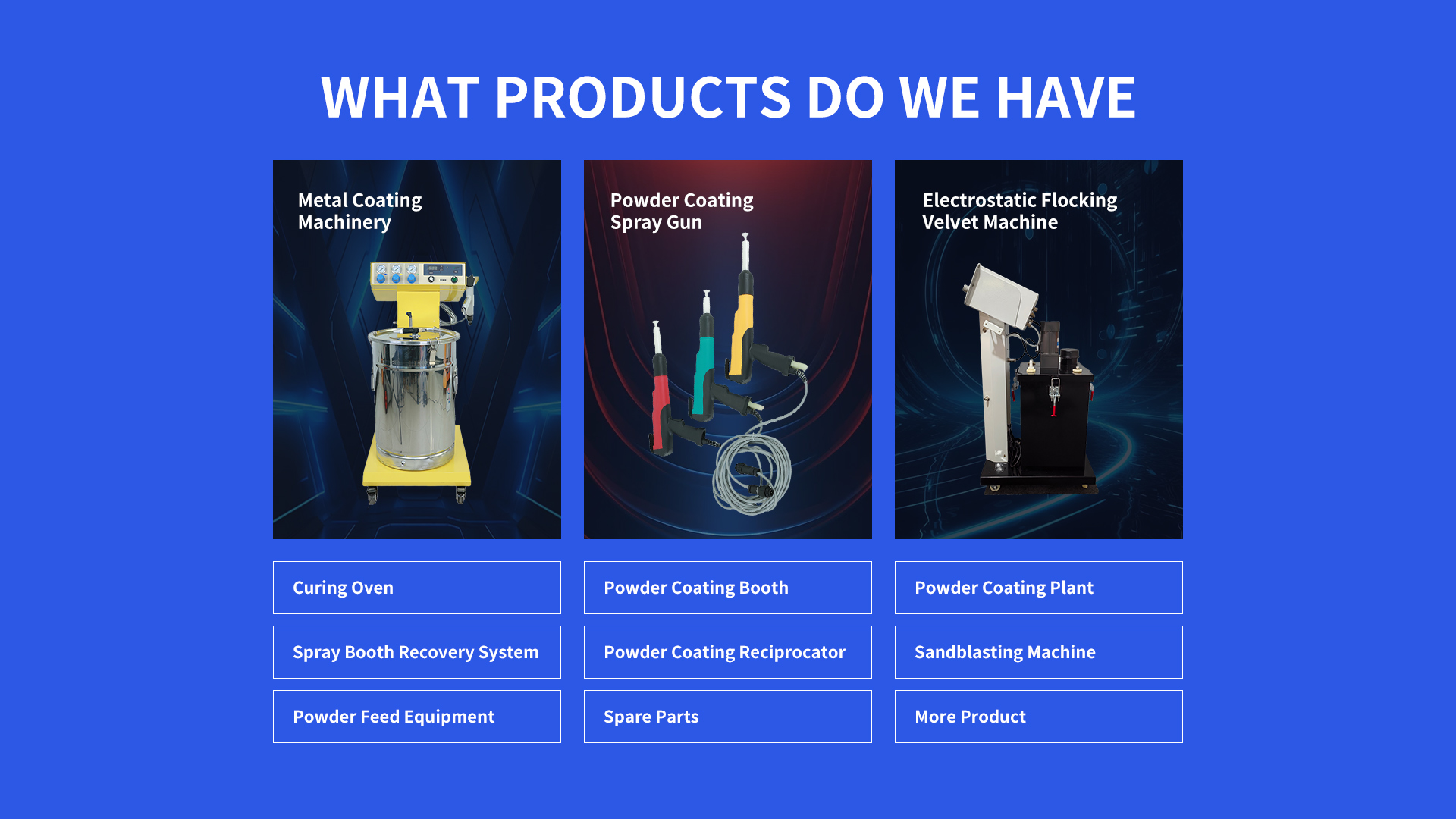

Disclaimer: Enhance your coating process with advanced electrostatic powder coating machines, precision powder coating spray guns, comprehensive powder coating systems, and efficient powder coating lines from Hangzhou Huaxiang Coating Equipment Co., Ltd. Designed for reliability and high-quality finishes, our solutions meet all your industrial powder coating machine needs. Contact us at sale3@cncolourspray.com